1. Gịnị bụ welded cylinder?A na-agbakọta gbọmgbọm ahụ ozugbo na okpu ngwụcha na ọdụ ụgbọ mmiri ndị ahụ na gbọmgbọm ahụ.A na-agbachikarị ma ọ bụ na-agbanye eriri n'ihu n'ihu n'ime gbọmgbọm cylinder ahụ, nke na-enye ohere ikpochapụ mkpanaka mkpanaka piston na akara mkpanaka maka ọrụ.Silinda hydraulic welded nwere ọtụtụ uru karịa taịlị mkpanaka.Ọ bụ ezie na tie mkpanaka cylinders nwere ike dị ọnụ ala karịa imepụta, a na-ewerekarị ha dị ka ihe dị ka "n'elu shelf" ma nwee oke nhọrọ n'ihe gbasara nhazi.Ha adịghịkwa adịte aka karịa cylinders welded.Enwere ike ịmezi cylinder ahụ nke welded maka ngwa ngwa.Silinda welded nwekwara ngwugwu akara dị elu, nke nwere ike inye aka mee ka ndụ cylinder dịkwuo elu ma nwee ike ịba uru mgbe a ga-eji cylinder mee ihe na ebe ndị metụtara mmetọ na ihu igwe.N'ụzọ mara mma, cylinders ahụ welded nwere profaịlụ dị ala karịa tie mkpanaka cylinders ma nwee ike melite ọdịdị nke akụrụngwa eji ya.Ebe ọ bụ na ha dị warara karịa ihe nhata ha, hydraulic cylinders welded na-arụ ọrụ nke ọma na ngwa nke oghere bụ ihe kpatara ya.

2. Olee otú ịchịkwa ịgbado ọkụ àgwà n'oge uka mmepụta?

Ngwa ịgbado ọkụ;Kwadebe ihe nlele ịgbado ọkụ nke ọma dị ka usoro a kara aka siri dị: ịgbado ọkụ, ịgbado ọkụ, nchekwa ọkụ, na ịkwadebe nlele ịgbado ọkụ.Na ime kaadị usoro ịgbado ọkụ iji nye ihe ndabere maka mmejuputa nke ịgbado ọkụ;Ihe eji agbado ọkụ, waya ịgbado ọkụ na gas ịgbado ọkụ bụ ihe edo edo, arụmọrụ kwụsiri ike, ịdị ọcha gas dị elu, yana oke ziri ezi;Onye na-agbado ọkụ, kwesịrị ịnwe asambodo welder;Nnwale ịgbado ọkụ, dị ka nyocha ike bead weld na nnwale ultrasonic iji lelee ogo ịgbado ọkụ.

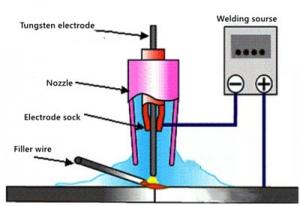

3. Enwere ike kewaa ịgbado ọkụ na-ekpuchi gas na inert gas shielded welding (TIG welding), gas na-arụ ọrụ ịgbado ọkụ (MAG welding) .Gas na-agbado ọkụ (TIG na MIG welding).N'ụzọ doro anya, a na-ejikarị argon eme ihe n'ihi ọnụ ahịa ya dị ọnụ ala karị, ya mere a na-akpọkwa ịgbado ọkụ na-ekpuchi gas na-ekpuchi ígwè dị ka argon arc welding.Tungsten inert gas ịgbado ọkụ bụ usoro ịgbado ọkụ nke tungsten ma ọ bụ tungsten alloy na-eji dị ka ihe electrode ihe, na arc na-emepụta n'etiti electrode na isi ihe na-eji agbaze isi ihe na jupụta waya n'okpuru nchebe nke inert gas. .

TIG, nke a makwaara dị ka Gas Arc Welding (GTAW), bụ usoro nke ime Arc n'etiti Tungsten electrode na base metal n'okpuru nchebe inert gas nke mere na ihe mgbakwasị ụkwụ na ihe mgbado ọkụ nwere ike gbazee wee gbanye ya.Ọ gụnyere ịgbado ọkụ DC TIG na ịgbado ọkụ AC TIG.

DC TIG ịgbado ọkụ na-ewere a DC arc ịgbado ọkụ isi iyi dị ka a ịgbado ọkụ ike, na oké njọ ike na nti isi ihe.A na-ejikarị ya maka ịgbado ọkụ igwe anaghị agba nchara, titanium, ọla kọpa na ọla kọpa alloy.Isi iyi nke ịgbado ọkụ AC TIG sitere na AC arc, na anode na cathode nke isi ihe gbanwere.EP polarity electrode overheating nwere ike wepụ isi ihe n'elu oxide oyi akwa, tumadi eji maka aluminum, magnesium, na ihe ọzọ alloy ịgbado ọkụ.

Mgbe TIG (GTAW) ịgbado ọkụ ọrụ, welder nwere ike ịbụ a ịgbado ọkụ egbe na otu aka na ịgbado ọkụ waya n'aka, adabara obere-ọnụ ọgụgụ ọrụ na ịrụzi nke ntuziaka ịgbado ọkụ.Enwere ike ịgbanye TIG ihe fọrọ nke nta ka ọ bụrụ ọla niile nke ụlọ ọrụ mmepụta ihe, ọ na-enye ọdịdị ịgbado ọkụ dị mma, obere slag na uzuzu nwere ike iji ya mee ihe na efere nchara dị gịrịgịrị.

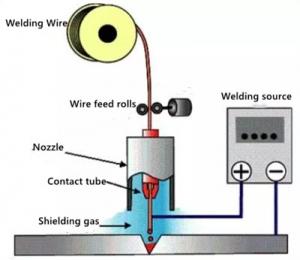

MAG (Metal Active Gas) Welding na-eji CO₂ ma ọ bụ ngwakọta nke argon na CO₂ ma ọ bụ oxygen (ihe na-arụ ọrụ gas).A na-akpọ ịgbado ọkụ CO₂ gas mgbe ụfọdụ dị ka ịgbado ọkụ CO₂ arc.Akụrụngwa ịgbado ọkụ nke MIG na MAG yiri nke ahụ n'ihi na enwere ike iji igwe na-enye waya akpaaka na-enye ha nri na ọkụ ma dabara adaba maka ịgbado ọkụ akpaka, ọbụghị maka ịgbado ọkụ n'aka.Isi ihe dị iche n'etiti ha dị na gas na-echebe, nke mbụ na-echebe ya site na argon gas dị ọcha, nke kwesịrị ekwesị maka ịgbado ígwè na-abụghị ígwè;MAG ịgbado ọkụ tumadi na-eji CO₂ gas, ma ọ bụ argon agwakọta CO₂ arụ ọrụ gas, ya bụ Ar + 2% O₂ ma ọ bụ Ar + 5% CO₂, adabara ịgbado ọkụ elu ígwè na elu alloy ígwè.Iji melite arụmọrụ usoro nke CO₂ welding, CO₂+Ar ma ọ bụ CO₂+Ar+O₂ ngwakọta gas ma ọ bụ flux-cored waya nwekwara ike iji.A na-eji MAG welding mara site na ịgbado ọkụ ngwa ngwa ya, nrụpụta mmalite mmalite dị elu, ọdọ mmiri miri emi, arụmọrụ dị elu, ọdịdị dị mma, ọrụ dị mfe, dabara adaba maka ịgbado ọkụ dị elu MIG (GMAW).

Emere ngwa ngwa na R&D na nrụpụta nkehydraulic cylindersna usoro hydraulic, na-ejere ndị ahịa ozi na inye ndị ọrụ ndụ ka mma.Ka ọ dị ugbu a, anyị enyerela ọtụtụ puku ndị ahịa aka n'ụwa niile na-enye ọkachamara na hydraulic cylinder na nhazi usoro na uru asọmpi.

Oge nzipu: Sep-16-2022